VGD propose différents produits et services simples à déployer permettant d’accroître vos rendements tout en garantissant la préservation, voire l’amélioration des propriétés organoleptiques de vos cultures. Notre motivation est portée par la considération du double enjeu qui est l’attente des consommateurs en terme de qualité et de respect de l’environnement et la nécessité, pour vous, de produire dans l’optimisation de la qualité de vos cultures. Notre ambition est de tout mettre en œuvre pour que vous puissiez obtenir le meilleur de vos exploitations, car nous sommes conscient de la charge de chaque investissement et de la nécessité de trouver des réponses efficaces, à long terme, face aux aléas climatiques que nous connaissons.

Gamme de luminaires

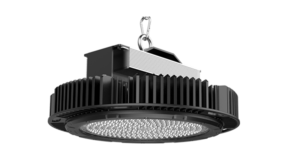

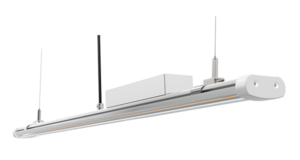

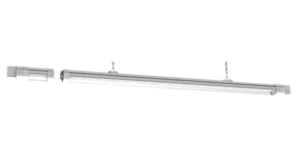

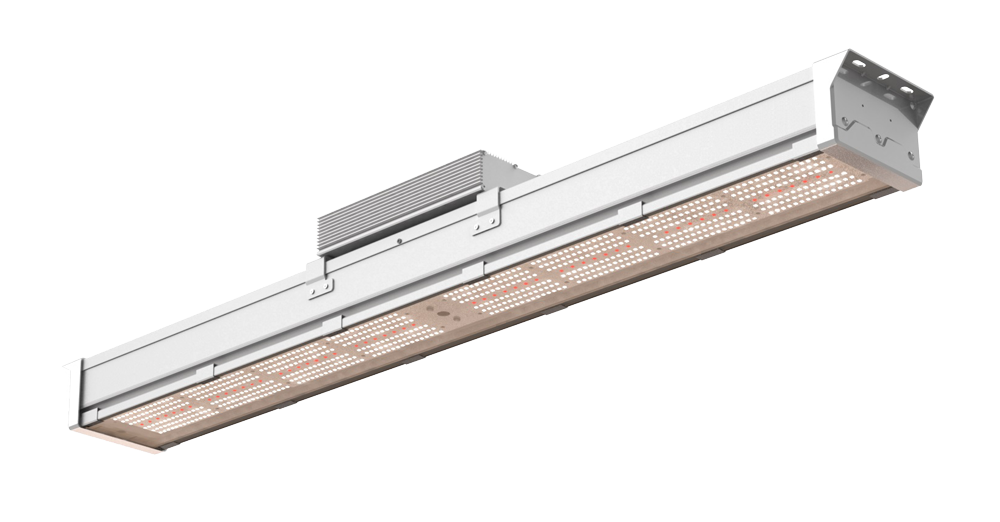

Luminaire multispectral

Gamme de Leds pour l’horticulture pilotables, 100% made in France. Chaque longueur d’onde peut être programmée simplement depuis une interface de gestion ergonomique et sécurisée. Développée en partenariat avec le leader de l’éclairage Airis (présent dans 17 pays) et testé et expertisé par la référence incontournable du secteur le CTIFL.

Multispectral

6 longueurs d’onde pouvant être contrôlées indépendamment en temps réel.

Gamme complète

Différents modèles adapté à chaque culture en position top, rack ou vertical.

Simple et durable

Installation en quelques jours avec nos partenaires agréés.

Durée de vie > 50 000 heures (15 ans)

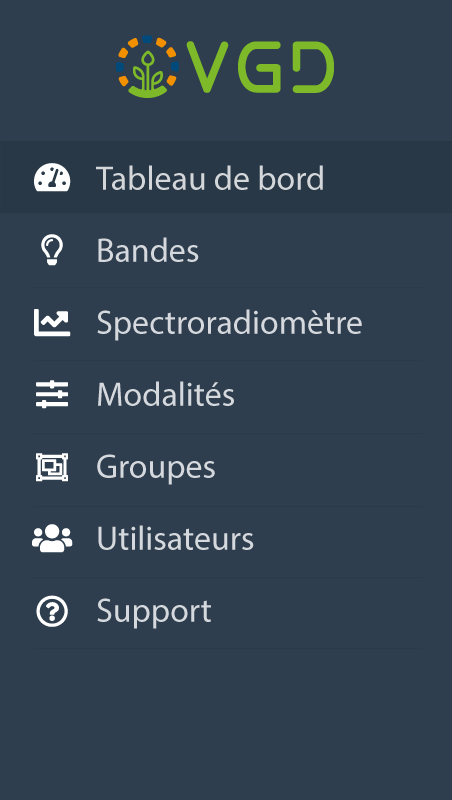

Luminaire personnalisé

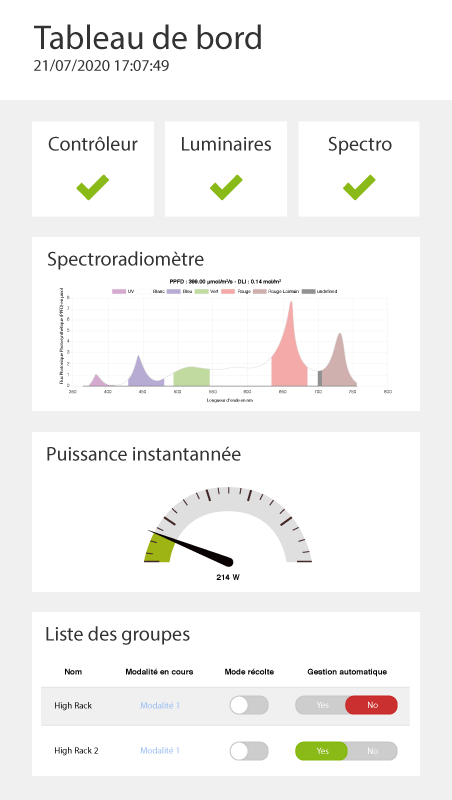

Le logiciel de pilotage permet, depuis une interface ergonomique, de paramétrer en amont les éclairages et les cultures par parcelle, de programmer les niveaux de luminosité et les objectifs d’éclairage pour une période donnée.

Ergonomie

Suivez le bon déroulement des opérations en un seul coup d’œil.

Management

En un clic, accédez à la supervision de toutes les modalités et au bon suivi de chaque zone différemment cultivée.

Statistiques

Visualisez vos données, traitées et analysées par nos experts.